| Business Type | Manufacturer, Exporter, Supplier, Trader |

| Country of Origin | India |

| Condition | New |

| Material | Stainless Steel |

| Click to view more | |

Product Details

Khoya and paneer making machines are specialized equipment designed to efficiently produce these dairy products. Here's a breakdown of their features and functions

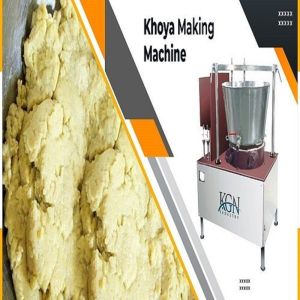

Khoya Making Machine

Purpose: Converts milk into khoya (or mawa), a concentrated milk product used in various Indian sweets and desserts.

Khoya Making Machine

Process: The machine heats and evaporates the water content of milk, resulting in a thick, semi-solid mass.

Types:

Tilting Khoya Making Machine:

Uses a tilting mechanism to facilitate the removal of khoya.

Tilting Khoya Making Machine

Fixed Vessel Khoya Making Machine:

Has a fixed vessel and requires manual removal of khoya.

Fixed Vessel Khoya Making Machine

Paneer Making Machine

Purpose: Curdles milk to produce paneer, an Indian cheese used in various dishes.

Paneer Making Machine

Process: The machine heats milk to a specific temperature and adds an acidulant (like lemon juice or food-grade acid) to curdle the milk proteins. The curdled milk is then separated from the whey and pressed to form paneer.

Types:

Manual Paneer Making Machine:

Requires manual operation for heating, curdling, and pressing.

Manual Paneer Making Machine

Semi-Automatic Paneer Making Machine:

Automates some steps like heating and stiring.

SemiAutomatic Paneer Making Machine

Fully Automatic Paneer Making Machine:

Automates the entire process, from milk heating to paneer pressing.

Fully Automatic Paneer Making Machine

Combined Khoya and Paneer Making Machines

Some machines are designed to produce both khoya and paneer. These machines typically have a larger capacity and more features than single-purpose machines.

Capacity: Choose a machine that matches your production needs.

Automation Level: Consider the level of automation required based on your labor availability and budget.

Material: Stainless steel is the preferred material for food processing equipment due to its durability and hygiene.

Fuel Source: Some machines can operate on different fuels like LPG, diesel, or electricity.

Brand Reputation: Choose a reputable manufacturer with good after-sales service.

I hope this information is helpful!